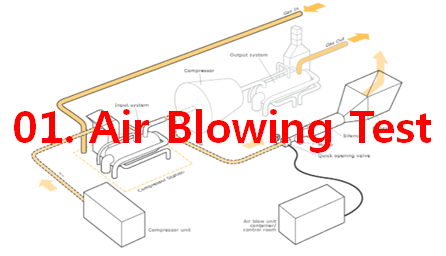

Air Blowing can be used as a safer, more environmentally friendly and cost effective alternative to conventional cleaning and steam blowing. The purpose of air blowing is to remove loose scale and debris prior to start up using compressed air as the cleaning medium. The velocity of a large air mass through the pipeline will pick up any debris or loose scale left in the pipe. This method will guarantee the cleanliness of the compressor or turbine suction pipeline and prevent damage.

Air Blowing Test 는 플랜트 공사에서 주로 이뤄지는 활동입니다.

배관공사가 끝날 때에(Pre commissioning) 배관 안에 남아있는 이물질 및 오염물질 제거, 습기제거, Dry, Drain 등을 위하여 이뤄지고 있습니다. Utility Line 또는 고압펌프 등을 사용하여 이뤄지는데, Utility Line은 생산 공장 마다 차이는 있겠지만 일반적으로 5~12 bar로 짐작해봅니다.

아래 내용에 Ear plug, Whip Checks 등도 추가해도 좋겠네요.

| Hazard Category | Hazards | Controls |

| Injury to peronnel and property damage | 1. As a result of low safety awareness or incorrect information 2. Non compliance of safety regulation & procedures |

1. Obtain correct PTW 2. Task supervisor to conduct pre-start meeting on daily basis and discuss all relevant hazard to the job with the crew and what corrective action are required before/during and at completion of job and sign attendance sheet. 3. Task supervisor to explain JSA to all employees and sign attendances sheet 4. Confirm that procedures and other associated documents are approved and available. |

| Slips and Trips | 1. Cause by inadequate access and poor visibility |

1. Ensure proper wind up of hoses and housekeeping at work site. 2. All work areas are to be kept clean and free of tripping hazards. 3. The accessories (hoses & pump) not being used must be disconnected and store separately 4. Adequate lighting for night work is to be provided or when lighting is poor |

| Serious or Fatal Injury | 1. Accidentally sudden release of air pressure & debris from discharge end of pipe or any valve spindle gland, gasket and flange 2. Defective tools can damage equipment and damaged equipment can leak due to high pressure |

1. Barricade the area where air blowing test is to be carried out 2. Post warning signs 3. Appropriate PPE (Personnel Protective Equipment) such as safety helmet, safety glasses, leather gloves and safety shoes shall be worn by all employees 4. Ensure the equipment and tools to be used for air bloving (such as hoses, pump, couplings, pressure gauges, gasket etc.) are free from any defect and suitable for the pressure rating of the system 5. Whiplash arrestor must be installed with every joint of hose connector. |

| Stuck or Hit to personnel |

1. Can occur sudden release of air pressure & debris |

1. Barricade the both end of pipe, provide warning signs like "danger, air blowing test in progress" 2. Unauthorized Personnel keep out 3. Spotters shall be assigned on both end of pipe in order to keep all personnel away from the test area. 4. A screen is provided in proper way to protect the personnel from flying debris |

| Physical Injury from flying debris |

1. Flying foreign particles from pipe 2. Exceeding Maximum allowable pressure |

1. An empty drum with number of holes or a screen around end of pipe shall be well supported and placed in front of polythene sheet to receive the debris from pipe 2. A screen should be provided at the end pipe to protect the foreign particles to hit someone and the area must be cordoned off 3. Ensure that the pressure gauge is calibrated and the task supervisor monitoring and not allowing pressure more than allowable pressure |

'Safety > JSA_JHA (위험성평가)' 카테고리의 다른 글

| 05. Bolt Tightening and Torquing (0) | 2022.12.11 |

|---|---|

| 04. Backfilling Work (0) | 2022.12.11 |

| 03. Asphalt Works (0) | 2022.12.11 |

| 02. Air Flushing (1) | 2022.12.11 |

| JSA (Job Safety Analysis) (0) | 2022.12.11 |

댓글