신규채용안전교육으로 쉽게 이해 할 수 있습니다.

프로젝트 성격 및 목적에 맞도록 자체적으로 준비하야합니다.

처음 현장에 들어오는 직원/근로자를 위한 교육으로 모든 사람은 안전수칙을 이해하고 지키기위하여 기본적인 안전관리 사항을 교육하고 있습니다.

일부 기업의 경우, Induction Training에 CEO의 영상 메세지를 넣어, 기업의 안전관리 의지를 보여주기도 합니다.

[Contents]

[Target & Goal]

[Project HSE Policy]

[Layout - Plant area]

[Layout - Site]

[Personal Protective Equipment]

Performing the work on project sites must take every resonable preautions as properly used and maintained PPE to eliminate any potential hazards to the workers..

[Personal Protective Equipment - 1. Head Protection]

All personnel working or visiting the site must wwear a safety helmet

(ISEA/ANSI Z89.1, Requirements for Protective Headwear for Industrial Workers)

[Personal Protective Equipment - 2. Feet Protection]

All personnel working or visiting the site must wear a safety shoes

(ASTM F117, Standard Specification for Dielectric Overshoe Footwear)

(ASTM 2412, Standard Test Methods for Foot Protection)

(ASTM 2413, Standard Specification for Performance Requirements for Foot Protection)

[Personal Protective Equipment - 3. Eye & Face Protection]

Eye & Face protection must be worn for specific operations

such as chipping, burring, grinding and welding

[Personal Protective Equipment - 4. Ear Protection]

Ear protection must be worn in all locations

where the ambient noise levels

at or above 85 deibels

[Personal Protective Equipment - 5. Full Body Harness & Lanyard]

When working at heights of 1.8 meters or greater.

A full body harness with shock absorber lanyard must

be used at all times.

[Personal Protective Equipment - 6. Respiratory Protection]

Respiratory protetion must be worn in area where fresh air may not exist

such as in confined spaces where toxic air or substances might be present.

[Personal Protective Equipment - 7. Electrical Protective Equipment]

Personnel working on electrical distribution systems must be provided

with the appropriate electrical protective equipment

[Machine & Hand Tools Safety]

The majority of accidents are caused by using an incorrect tool for the job.

It is essential that the correct type, size and weight of tools should

be decided before any work is carried out.

[Equipment & Devices]

Equipment & devices must be inspected and tested by competent personor electricians on arrival at the onstruction site and in compliance with the national and local laws and regulations.

[Permit to Work - PTW]

Permit to work system provided a means of communication

between site maintenance, operators and manages

and a record of this communication.

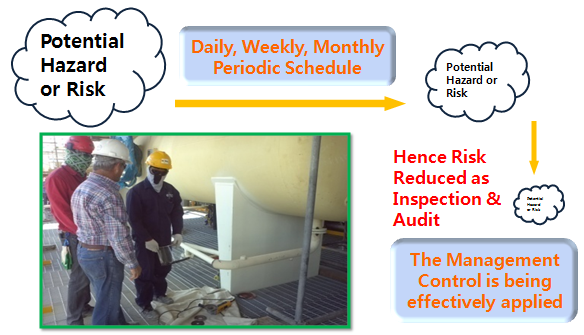

[Inspection & Audit]

HSE staffs are performing a inspetion and audits at site in a periodic schedule

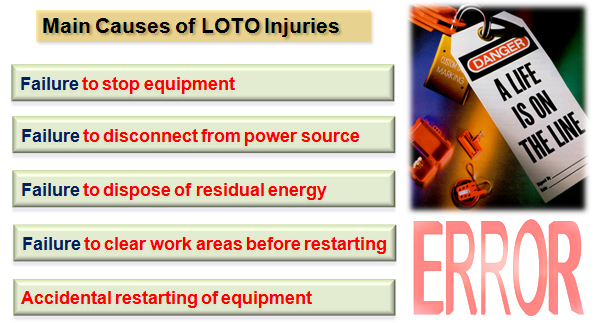

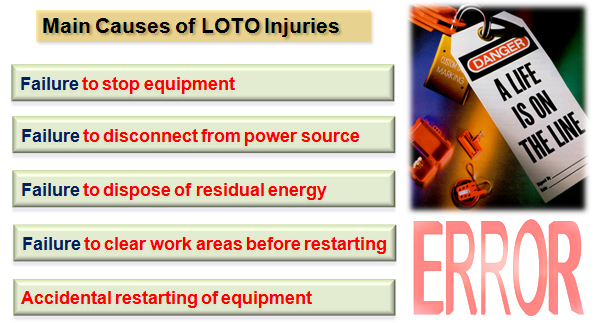

[Lock out & Tag out]

To prevent release of energy accidentally while a machine or equipment is being worked on;

[Heat Stress]

To prevent release of energy accidentally while a machine or equipment is being worked on;

'Safety > safety training' 카테고리의 다른 글

| Electrical Safety (1) | 2022.12.11 |

|---|---|

| Confined Space Work (0) | 2022.12.11 |

| Safety Training (0) | 2022.12.09 |

| Crane & Lifting (0) | 2022.12.09 |

| Control of Hazardous Substances (1) | 2022.12.09 |

댓글